Sinowolf Plastic Dekor Co.,Ltd

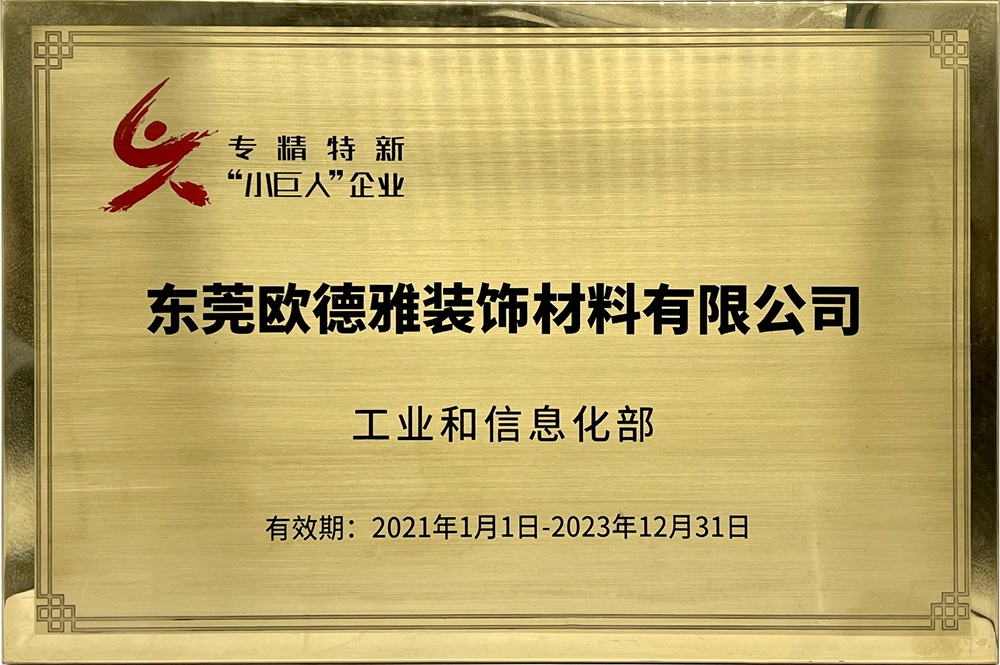

FavoritesAbout SINOWOLF Plastic Dekor Co., Ltd: Established in October of 2007. 500 more workers. 25000 square meter factory area.17 years professional experience in Edge Banding. Germany imported machinery, technical support, raw material and UV ink. Europe furniture edge banding quality. ISO,SGS,BV and ITS certificated. Produce ability is about 1,000,000 meters one day. Another two factories: one was set up in Zhejiang province in 2017, another new one set up in Zhaoqing City 2023. For now we have thousands printing designs and hundreds emboss moulds. Welcome to contact us for more informations."Sinowolf is a modern enterprise, engage in the edge banding manufacturing and sales for the panel furniture industry , the headquarters is located in Zhaoqing.Sinowolf is committed to the high-end R&D, production and sales of plastic edge banding. Up till now, we have obtained 27 national invention patents, the “Made in Zhejiang” certificate, we are the National Level Specialized and Innovative Little Giant as well. Our products covering PVC, ABS, PP, PMMA and the other edge banding materials. At present, we are supplying over 1.0 billion meters of edge banding for the furniture industry per year, featuring of high-quality and environmental friendly. It is our philosophy to maintain the integrity, responsibility, and to provide the customers the edge banding with EU quality standard and solutions. The Dongguan subsidiary was founded in 2017, located in Dalang Town, Dongguan City, with an occupied area of 26,500 sqm. The Zhejiang subsidiary was founded in 2017, located in Huzhou City, Zhejiang Province , with an occupied area of 15,300 sqm. The Zhaoqing subsidiary was put into operation in 2024, with an occupied area of 50,000 sqm. In addition, we have sales offices also in the northeast China, Hubei, Sichuan, and Shandong etc."

-

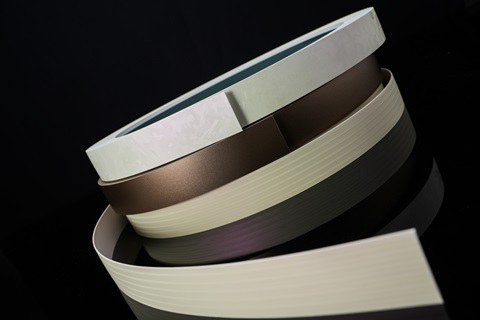

PVC edge banding

PVC edge banding:customized edge banding follow customers' design with superior raw materials and offer superior products to customers.

-

ABS (acrylonitrile butadiene styrene)

ABS (acrylonitrile butadiene styrene) is an impact resistant, Mechanically and thermally resilient, high quality thermoplastic which is ecologically sound. For over 20 years now, this chlorinefree plastic has been successfully used in the furniture industry. It is the outstanding application, processing and disposal characteristics, in particular, of ABS that contribute to its extensive impact on the furniture manufacturing market.

-

Digital Printed Edge Banding

1. Sinowolf digital printed edge banding, clear color, delicate texture, abundant colors. 2.Sinowolf technology research& development, product iteration, always walk in the forefront of market. Sinowolf has its own digital design center and printing equipment, you can design according to your panel surface, and print the edge design directly, high production efficiency, showing up to what you see is what you get. 3. Sinowolf digital printed edge banding can enjoy the customized service, any logo, graphics, as long as the design draft, not only designers, customers can also provide the desired picture, DIY, to achieve the infinite possibility of edging.

-

PET Aluminium Edge Banding

1. Sinowolf metallic edge banding, with PET material to replace the traditional metallic aluminum film, in the processing , greatly reduce the damage of the trimming knife, and the edge is no serration, it is smooth and neat, more can highlight the quality of furniture products. 2. With PET film could realize more colors, a variety of textures with metal effect, the same metallic luster and texture, supporting high-grade cabinets, door boards and other home products, can meet an abundant of colors, richer texture edge design needs, can also bring better experience to consumers.

-

PP Edge Banding

PP (polypropylene) belongs to the semi-crystalline material, it belongs to the polyolefin. The semicrystalline structure casts its physical properties and has a high melting point. Due to its characteristic low density of 0.9, PP is one of the lightest thermoplastics. In addition, PP (polypropylene) is also an ecological and sustainable thermoplastic material, with excellent material and processing properties. Mainly used in pipe extrusion and packaging industry, and furniture industry. PP provides significant chemical properties and sustainability beyond other materials.

-

Veneer Edge Banding

1. Sinowolf veneer edge banding, using the solid wood surface + PVC substrate composite process, not only retains the natural solid wood texture, but also greatly improve the toughness and quality of the edge banding, effectively solved the traditional solid wood edge banding easy to brittle, easy to break, edge burr and other problems. 2. At the same time, it has a natural solid wood texture, which perfectly integrates with the solid board to achieve the effect of integrating the whole board, which is more in line with the needs of high-end customized customers.

Company Introduction

Trade background

Trade background

Main Market

Main Client Types

Annual Export Revenue

60,000,000 RMB Production Capabilities

Production Capabilities

Customization Options

Quality Control

New Products Launched in Last Year

Company Overview

Certifications

Send message to supplier

Join us to connect with brands

Sign up to easily connect with your favorite brands and make the most of your experience.

Explore

Browse products from countless suppliers

Get Inspired

Find on-trend products and fresh ideas

Connect

Reach out to suppliers quickly and easily

Welcome back! Already have an account?