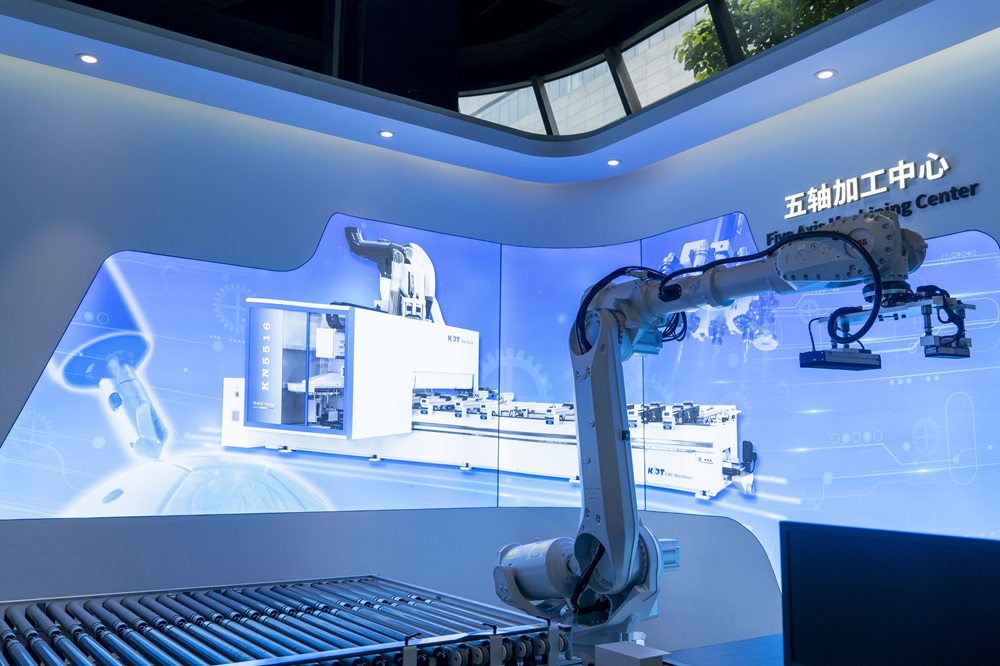

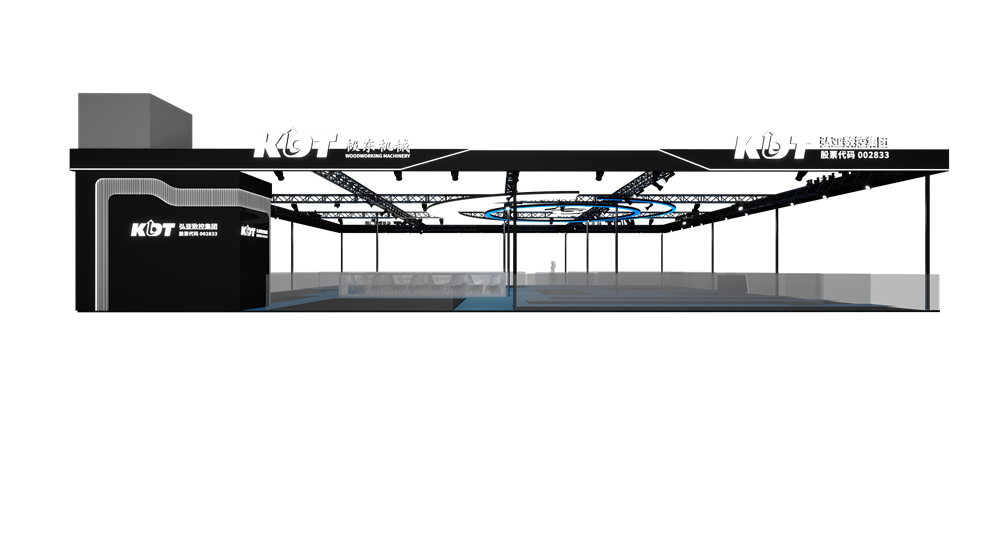

Guangzhou KDT Machinery Co.,Ltd.

Favorites"Guangzhou KDT Machinery Co., Ltd is a corporate who public listed in Shenzhen Main Stock Exchange (Ticket symbols: 002833). With headquarters in Guangzhou High-tech economic zone, KDT also built up its R&D center and production center in Italy. Specialized in R&D and manufacture in the high-end furniture machinery, KDT sales network globally covers more than 70 countries with its core products such as edge bander, panel saw, CNC machining center, NC drilling center, flexible automation line and packaging solutions etc., which widely won praise from customers at home and abroad. Leading top position in the worldwide machinery industry, KDT is honored as one of the top 500 Chinese machinery enterprises. With the pursuit of “Win-win cooperation, and creates value for customers”, KDT truly partners with our customers, agents and employees around the world for success. "

-

KDT front-loading panel saw KS-828D

KDT front-loading panel saw KS-828D is newly upgraded. Increasing the motor torque, making the main and scoring saw more stable on working, much accurate on positioning and more compact on the arrangement of the 8 grippers which can meet the clamping requirement for different sizes of panels. It creates an excellent sawing experience. Main Saw auto position(Patented) Intelligent Control; Accutare positionning and grooving; sawing efficiency increase by 30%. Scoring Saw Adjustment Quick centering and depth adjustment. Side-Aligner Ensures a stable running; saves time in positioning and leads to an accurate position with small boards.

-

Nesting model KN-2409LP

Nesting model KN-2409LP standard equips with Cam software to achieve efficient cutting, features in quick replenishment function , effectively shortens production real-time labeled and improve the operation experience. Fast Panel Replenishment No need to re-set the program, it can replenish panels directly. If any problem on panel processing, it can be quickly optimized into unprocessed files. Efficient Routering High efficiency on panel cutting without lifting tools up. 9kW spindle for quality routering. Position Rail Equipped with guide rail for unloading, make sure correct position. Standard With PC Control Configure KDT operation software interface, real-time monitoring of equipment status and docking process statistics from factories.

-

Rectangular laser KE-520GU Laser 3.0S

Rectangular laser: Optimize the spot, leading to an even distribution in energy and temperature control. High-quality workpiece appearance: Beautiful, durable, eco-friendly 1、0”glue line, more streamlined appearance. 2、High adhesion, strong sealing strip, waterproof, moisture-proof and more durable. 3、High sealing performance. It releases maximally formaldehyde and keep inside the board, reducing air pollution. Rugged Frame Based frame processed with large-scale gantry milling, make sure high precision and quality. PUR changeover pot Enables fast switching between multiple colors of glue. Laser Unit No need to preheating, it can instant edge sealing, save time and labor. Sealing edge without glue line, high sealing performance and strong adhesiveness. Horizontal End Cutting Unit Highly efficiency, the minimum board distance is 450 mm and the maximum bevel cutting angle is 25°.

-

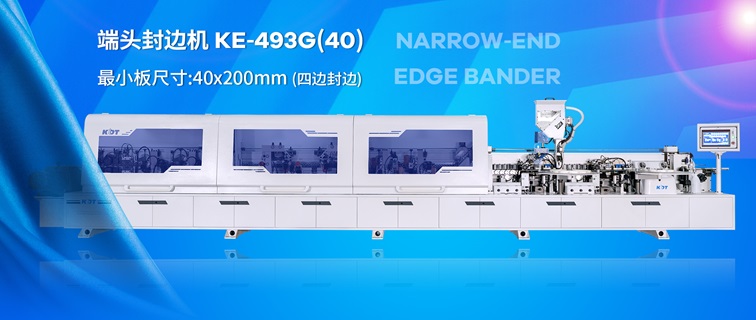

High speed edge bander KE-493G(40)

High speed edge bander KE-493G(40), automated, high efficiency and precision, bring you a wonderful home. PUR changeover pot + Pre-melting system Quickly changes various colors of EVA and PUR glue. Double Rail End Cutting Motions along the precision linear guide, cut off the excess edge at front and rear of the panels quickly. Ensure a smooth cut surface. High Speed Corner-rounding Equips with 4 trimming motors, fast and stable in corner profiling. Double Reciprocating Buffing Cleans off chips on top & bottom of the panel surface.

-

KDT six-sides drilling machine KD-612CSD

KDT six-sides drilling machine KD-612CSD which integrates drilling and milling function. High efficiency and precision. Equipped with three drill sets and four spindles. It can rapidly position and achieve six-sides drilling, grooving and milling. With diversified high-end modular process libraries, quick selection and easy to edit. Creating unlimited possibilities for furniture manufacturing. Layout of drill set unit Upper and bottom drills package coordination working, wide processing range. Optimize drilling layout and improve the working efficiency. Electrical Spindle For Side Routering 6kW electrical spindle equipped on the left upper drill head that can be tool-changed with side aggregate to realize routering or grooving at each different side. 2 layers 6-post ATC spindle 5.5kW automatic tools changer equipped on the right; Available for storing tools and blades with various specification, automatically identifies tools location. Dual Bottom Spindle Available to install grooving tools and straighter tools, satisfies higher requirement on grooving accuracy. Upgraded Software Proactive drilling: Plan the optimal path through AI ant Algorithm, realizes drill shaft pre-ejects, increasing the efficiency by 15%.

Company Introduction

Trade background

Trade background

Main Market

Main Client Types

Annual Export Revenue

Production Capabilities

Production Capabilities

Customization Options

Quality Control

New Products Launched in Last Year

Company Overview

Certifications

Send message to supplier

Join us to connect with brands

Sign up to easily connect with your favorite brands and make the most of your experience.

Explore

Browse products from countless suppliers

Get Inspired

Find on-trend products and fresh ideas

Connect

Reach out to suppliers quickly and easily

Welcome back! Already have an account?